THIS ARTICLE AT A GLANCE

CONTACT ETS

If you have any questions or would like to discuss further what you should be doing, ETS is here and willing to help.

Call 0117 205 0542

Email enquiries@energy-ts.com

Submit a contact form

CHECK OUR SERVICES

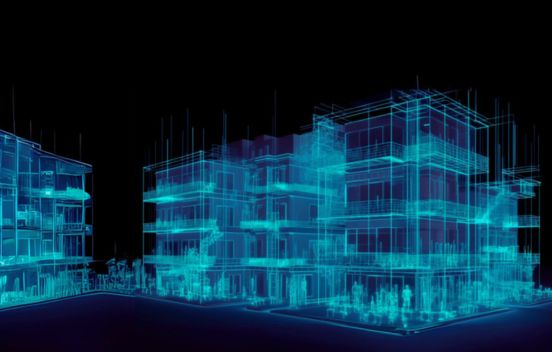

Date Palm Developments - Complete Building Solutions

Date Palm Developments (DPD) approached ETS to design, install, and commission a new Building Management System (BMS) for their proposed “Ottons Lab.” Given the complex nature of the facility, which specialises in plant cloning, highly detailed designs relating to HVAC controls and operational security were necessary to maintain optimal conditions for both plant growth and occupant comfort in the office areas.

The entire system was tailored to meet the client’s specific needs. This includes:

- Automatic Lighting Controls: Ensuring proper lighting levels for plant growth and energy efficiency.

- Precise Temperature Control and Monitoring: Maintaining the optimal environment within the growth rooms (+/- 0.1 °C).

- Air Handling Unit (AHU) Controls: Regulating building pressures throughout the facility and laboratories to prevent contaminants from entering cleanroom areas.

In addition to these features, ETS integrated various other items including a site-wide AC Variable Refrigerant Flow (VRF) system, an air source heat pump, chillers, meters and packaged close control AHU systems, making a truly smart building.

Client brief

DPD is a market leader for production of Date Palms by tissue culture. Pioneers in the field, DPD has over 30 years’ experience in the production of disease-free, true to type micro-propagated Date Palm plants. Using their unique system, DPD produce date palms of the highest quality available on the market today and have successfully supplied over 1.8 million of these plants to more than 25 countries across the date-growing world.

Challenge

Due to the complex nature of the site and the processes involved, DPD approached ETS requesting that we design and install a complete BMS and monitoring system for them.

The system would additionally be required to contain backup methods of control should a complete failure occur from one piece of the plant (HVAC or control).

ETS’s Scope included:

- Designing the system to accommodate future expansion and electrical upkeep by the trained onsite maintenance staff.

- Project management, handling various design and layout changes throughout the differing stages of the project.

- Ensure sensor and equipment status is logged and stored to the highest possible resolution for the longest possible time to aid future diagnostics relating to growth processes.

- Setting up advanced alarm handling as the first line of defence should a fault occur.

- Ensuring that the client can easily use the system and fully understand its operation.

- Full site-wide integration of various plant types through Modbus RTU/TCP and BACnet.

ETS’s Solution & Strategy

Client-Centric Building Solutions: ETS engaged closely with DPD to understand their specific requirements and challenges. This collaborative approach ensured that the BMS design would address all critical aspects of the laboratory and office environments.

Precision Engineering: Given the high stakes of maintaining exact conditions within the growth rooms, ETS prioritised precision in temperature control, air quality, and pressure management.

Seamless Building System Integration: ETS aimed to create a cohesive system that seamlessly integrated various components, such as lighting, HVAC, and underfloor heating, to provide a unified and efficient solution.

Our solutions are as below:

- Automated Lighting Controls: The BMS includes advanced lighting controls that automatically adjust based on the needs of the plants, optimising both growth conditions and energy usage.

- Temperature Control and Monitoring: ETS installed sophisticated temperature control and monitoring systems to ensure the growth rooms remain within the strict parameters required for plant cloning.

- AHU and Pressure Control: The AHU controls were configured to maintain the necessary building pressures, ensuring that pharmaceutical-level cleanroom standards are upheld by preventing foreign particles from entering sensitive areas.

- Integrated HVAC Controls: ETS integrated a site-wide AC Variable Refrigerant Flow (VRF) system along with an air source heat pump. This setup provides efficient climate control, including underfloor heating for the office areas, enhancing occupant comfort and energy efficiency.

By combining these elements, ETS delivered a robust and reliable complete building solutions that supports DPD’s operational goals and fosters a conducive environment for plant growth and research.

Results

ETS’s tailored BMS solution delivered outstanding results for Date Palm Developments. The precise environmental controls optimized plant growth and cloning efficiency, while automatic lighting and temperature systems minimised manual intervention. AHU and pressure controls-maintained cleanroom standards, preventing contamination. The integrated HVAC and underfloor heating systems enhanced office comfort and energy efficiency. Overall, ETS’s innovative approach exceeded DPD’s expectations, resulting in a reliable, efficient, and highly functional facility.

Complete turnkey solution (design, project management, installation, commissioning and handover).

Process control with top-class operational security.

Project handed over with a high level of client satisfaction.