THIS ARTICLE AT A GLANCE

CONTACT ETS

If you have any questions or would like to discuss further what you should be doing, ETS is here and willing to help.

Call 0117 205 0542

Email enquiries@energy-ts.com

Submit a contact form

CHECK OUR SERVICES

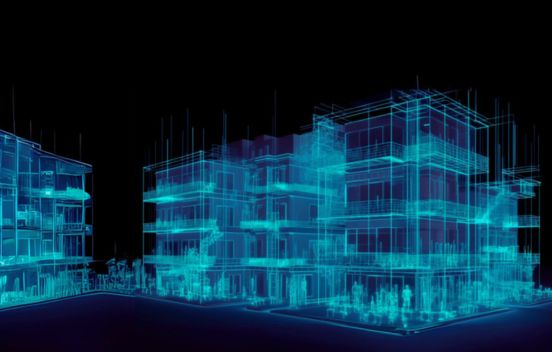

Sainsbury's – Superstore Upgrade with 20% energy reduction

Energy & Technical Services delivered a number of energy saving initiatives as part of Reset 7, Sainsbury’s 20 by 20 Sustainability Plan, comprising upgrades to the refrigeration packs, sales floor / back of house lighting, cold aisle heating, HVAC fans, BMS controls and store pressurisation to a 62,766 sqft Superstore.

The inefficient and aging F-Gas screw packs and associated condensers were replaced with new scroll pack internal units with external air-cooled condensers, F&R pipework and controls.

The existing T8 lights on the sales floor and back of house were replaced to LED and a new 22KW plug fan was installed to the HVAC unit. Works also included installing LPHW boilers and heating coils into the Air Handling Unit (AHU) as well as DHW calorifiers to boost heating requirements especially for the cold aisles. The existing Trend BMS set points / time schedules were also reset to improve energy efficiency.

Challenge

To enable the refrigeration plant installation and replacement, cabinets needed to be de-merchandised overnight during 2 weekends. Close consultation with multiple subcontractors, consultants and client representatives was essential to ensure all the various works / upgrades were completed out of hours and on time, so that trade was not impacted.

Added Value / Achievements

The combined works provided a pay back within 4.68 years with a store energy reduction of 20%.

UPGRADE complete WITHOUT TRADE IMPACT

20% of energy reduction