THIS ARTICLE AT A GLANCE

CONTACT ETS

If you have any questions or would like to discuss further what you should be doing, ETS is here and willing to help.

Call 0117 205 0542

Email enquiries@energy-ts.com

Submit a contact form

CHECK OUR SERVICES

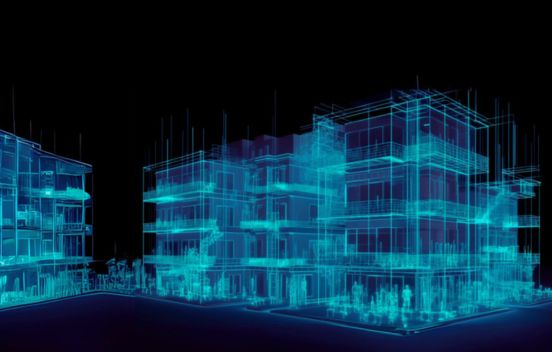

Sims Metal Management – Design & Specification

Energy & Technical Services was appointed to provide technical expertise on the design and manufacture of a new Dry Cooler, as the existing motor on the shredding plant needed to be replaced with a more operationally efficient model.

After successfully delivering the designs and specifications, we continued to work with client representatives to procure works for the commissioning of the new 4,476kWh water cooled motor before novating to Transtherm.

Our consultant identified a number of challenging environmental and working conditions during the initial site survey. Working closely with contractors and client representatives, our team ensured the new equipment would be easy to maintain and could operate under varying torque loads and temperatures.

Challenge

The design of the Dry Cooler and Controls needed to maintain motor temperatures between 250C to 300C in ambient conditions and operate under varying torque loads. Our consultants undertook complex rejected heat load calculations to ensure the recommended options would meet this requirement.

Added Value / Achievements

Our consultants’ valuable product knowledge and experience ensured our client was presented with the best options available and provided with appropriate guidance on maintenance / serviceability.

Technical expertise support and action

Controls remain to operate in the required condition