THIS ARTICLE AT A GLANCE

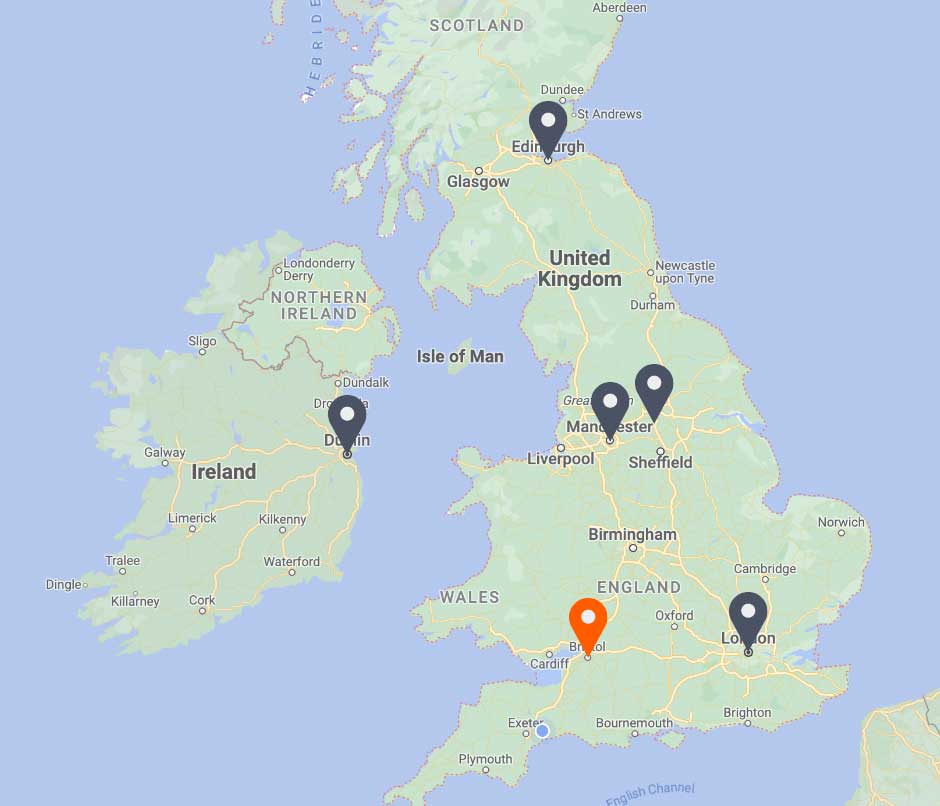

CONTACT ETS

If you have any questions or would like to discuss further what you should be doing, ETS is here and willing to help.

Call 0117 205 0542

Email enquiries@energy-ts.com

Submit a contact form

CHECK OUR SERVICES

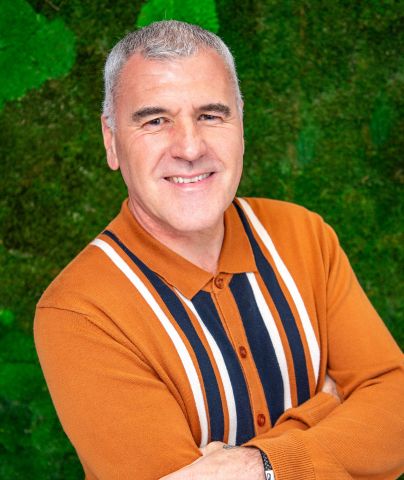

Woodie's - Decarbonisation & Energy Performance Audit

Energy & Technical Services has supported Woodie’s in decarbonisation and energy management for 6 years. In this case study, we provided a proven method to enable Woodie’s to decarbonise its portfolio, and budgetary figures were obtained to allow the implementation of decarbonisation replacement/installations.

Key Achievements include:

• Potential to eliminate 321,223 kWh of annual gas consumption.

• Proposed photovoltaic solution to enable the production of circa 70,000kWh of electricity annually.

• Suggested a destratification system, achieving savings of up to 20% in heating costs.

Client Brief

Woodie’s is a 100% Irish-owned DIY shop and a subsidiary of Grafton Group plc. They are the market leader in Ireland, with 35 branches across the country offering a wide range of DIY products. With a complex set-up and an extensive portfolio of buildings, Woodie’s looked to take a proactive approach to reducing their carbon footprint and meeting sustainability goals. In this case study, Energy & Technical Services, as a part of Woodie’s decarbonisation partners, supported the completion of a comprehensive decarbonisation plan based on their property in Dublin, Airside.

Challenge

Woodie’s has a large portfolio of properties that utilise central heating and cooling plants that run on fossil fuels. As a leading retailer, Woodie’s is committed to contributing to mitigating climate change risks by minimising its carbon footprint and overall environmental impact on decarbonisation. To achieve these goals, Woodies must move away from all plants that consume fossil fuels and implement sustainable technology as a replacement.

ETS’s Scope included:

- Visit the site and complete an energy performance audit of the store layout and existing heating, cooling, and ventilation systems.

- Undertake design calculations to provide the requisite hot water, heating, and cooling demands without the requirement for natural gas.

- Detail the operational philosophy of proposed new systems.

- Provide installation cost estimates for new systems.

- Analyse energy consumption and cost and identify carbon-saving opportunities.

ETS’s Solution & Strategy

The report includes a comparison of the current heating plant and a variable refrigerant flow heat pump system. All options were selected based on the most appropriate technology for Woodie’s Airside. Aspects such as decarbonisation, capital expenditure, operational expenditure, installation time, plant space and efficiencies were considered. A multi-disciplinary team was established across our Technical Services Team, and Energy and Carbon Savings Team, led by a Senior Consulting Engineer. The Technical Services Team completed the majority of the initial work, including the energy performance audit and technology review. Both teams then collaborated to ensure accurate and comprehensive calculations were completed in relation to the potential energy and carbon savings. Our end-to-end energy service team covers Woodie’s needs, from the site audit to the technical and strategic identified solutions. It supports Woodie’s declaring their progress against the Net Zero goals and having a more extensive decarbonisation strategy.

Results

With the aim of decarbonising the property at Woodie’s Airside, Energy & Technical Services recommended replacing the current heating plant with a Variable Refrigerant Flow (VRF) heat recovery system. The proposed VRF system ensured that Woodie’s Airside effectively eliminated the consumption of fossil fuels utilised for heating the property. Additionally, Energy & Technical Services suggested the implementation of a Photo Voltaic (PV) array to enhance the VRF system further. It was proven that the PV array can aid in offsetting the electrical consumption of the VRF system, which will significantly reduce the expected energy costs. Through data obtained by our team, it was calculated that the return on investment of the PV array would be 3.7 years, which is less than the average.

Proposed photovoltaic solution to enable the production of circa 70,000kWh of electricity annually.

Suggested a destratification system, achieving savings of up to 20% in heating costs.