THIS ARTICLE AT A GLANCE

CONTACT ETS

If you have any questions or would like to discuss further what you should be doing, ETS is here and willing to help.

Call 0117 205 0542

Email enquiries@energy-ts.com

Submit a contact form

CHECK OUR SERVICES

The Power of Smart Building Technology

What is Smart Building Technology?

The terms ‘Smart Building’, ‘Intelligent Building’, and ‘Building Automation’ are often used interchangeably, and the variation in the definition of these terms and their interpretation can be confusing for businesses when assessing the range of energy saving and ‘sustainable’ technologies available on the market.

With the ever-increasing scrutiny on the sustainability and environmental performance of property assets, and the seemingly inexorable rise of the ‘smart cities’ agenda, the notion of the smart building has gained increased exposure over recent years. However it is clear that smart building tech can include everything from automated building management systems, to HVAC plant monitoring platforms, to meeting room booking systems.

At its most basic level, a smart building can be said to use a combination of technologies to automate building management, removing the requirement for the manual control which can often cause inefficiency and poor environmental performance – although clearly one would hesitate to deem a building as being ‘smart’ simply because a BMS is in place!

Over time, and as technology in this space develops, the notional benchmark of what constitutes a ‘smart building’ also shifts – with expectations about the aspects of the property that should be ‘optimised’ and ‘connected’ including more and more factors.

However, in general, smart buildings are those where technology provides granular monitoring and control over plant and systems to optimise energy efficiency, occupant health & wellbeing, comfort levels, and security systems.

To achieve this, smart buildings increasingly exploit IoT connectivity, sensors, metering and controls to remotely monitor and proactively respond to occupant requirements by adjusting the buildings systems accordingly.

The Benefits of Smart Building Technology

Beyond improved efficiency and occupancy conditions, smart technologies can facilitate better decision making on investment decisions, and the future-proofing of assets through predicative maintenance to ensure operational resilience, ongoing compliance, and capital / rental value protection.

However, the emergence of new technologies and a rapidly evolving marketplace can often bring confusion and a level of uncertainty about which systems to choose and integrate – which can lead to either inaction, or the implementation of inappropriate solutions.

Migration to Smart Building Technology

Migrating over to smart building technology can seem like a daunting task especially when considering the level of sophistication required to set up the necessary controls automation, monitoring and reporting. However, depending on an organisation’s goals, size and business activities, it is possible to integrate smart technology within a building without the need for a complex or costly setup.

A BMS / BeMS is the core of any smart building agenda. Understanding its role and core functions to managing building performance is the first step towards achieving a smart building. Once this understanding is in place, further investigations into additional tech integration can be made, to ensure seamless operation and cohesive communication between disparate building systems.

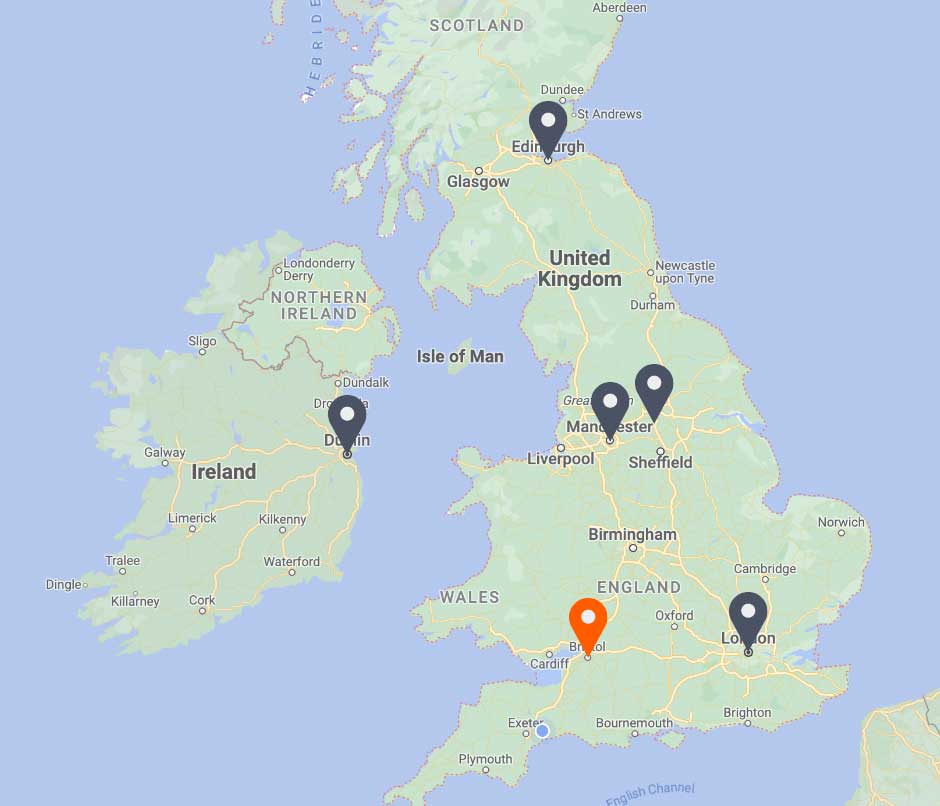

The ETS team can assist here, as we have the full range of specialisms and expertise under one roof: from analysts & data scientists, chartered building services engineers, building controls and automation specialists, and chartered energy managers.

With this level of integrated expertise, we can help your organisation make the move from ‘dumb’ to ‘smart’ buildings, to save significant amounts of money, proactively manage and reduce carbon emissions, ensure compliance, and protect the value of your property assets.

Get in touch with the ETS team, to explore how we can help! Call 0117 379 0850 or email enquiries@energy-ts.com.

More Answers

Final thoughts

If you are looking for an energy management system that is tailored to your business needs, ETS can provide you with 25 years of experience in dramatically improving energy efficiency and reducing environmental impacts. Whether your businesses have individual assets or large international portfolios, ETS can assist you in saving substantial amounts of money while significantly reducing your carbon performance.

To discuss your requirements, get in touch. You can contact us by calling 0117 205 0542 or drop us an email at enquiries@energy-ts.com.

What is Smart Building Technology?

The terms ‘Smart Building’, ‘Intelligent Building’, and ‘Building Automation’ are often used interchangeably, and the variation in the definition of these terms and their interpretation can be confusing for businesses when assessing the range of energy saving and ‘sustainable’ technologies available on the market.

With the ever-increasing scrutiny on the sustainability and environmental performance of property assets, and the seemingly inexorable rise of the ‘smart cities’ agenda, the notion of the smart building has gained increased exposure over recent years. However it is clear that smart building tech can include everything from automated building management systems, to HVAC plant monitoring platforms, to meeting room booking systems.

At its most basic level, a smart building can be said to use a combination of technologies to automate building management, removing the requirement for the manual control which can often cause inefficiency and poor environmental performance – although clearly one would hesitate to deem a building as being ‘smart’ simply because a BMS is in place!

Over time, and as technology in this space develops, the notional benchmark of what constitutes a ‘smart building’ also shifts – with expectations about the aspects of the property that should be ‘optimised’ and ‘connected’ including more and more factors.

However, in general, smart buildings are those where technology provides granular monitoring and control over plant and systems to optimise energy efficiency, occupant health & wellbeing, comfort levels, and security systems.

To achieve this, smart buildings increasingly exploit IoT connectivity, sensors, metering and controls to remotely monitor and proactively respond to occupant requirements by adjusting the buildings systems accordingly.

The Benefits of Smart Building Technology

Beyond improved efficiency and occupancy conditions, smart technologies can facilitate better decision making on investment decisions, and the future-proofing of assets through predicative maintenance to ensure operational resilience, ongoing compliance, and capital / rental value protection.

However, the emergence of new technologies and a rapidly evolving marketplace can often bring confusion and a level of uncertainty about which systems to choose and integrate – which can lead to either inaction, or the implementation of inappropriate solutions.

Migration to Smart Building Technology

Migrating over to smart building technology can seem like a daunting task especially when considering the level of sophistication required to set up the necessary controls automation, monitoring and reporting. However, depending on an organisation’s goals, size and business activities, it is possible to integrate smart technology within a building without the need for a complex or costly setup.

A BMS / BeMS is the core of any smart building agenda. Understanding its role and core functions to managing building performance is the first step towards achieving a smart building. Once this understanding is in place, further investigations into additional tech integration can be made, to ensure seamless operation and cohesive communication between disparate building systems.

The ETS team can assist here, as we have the full range of specialisms and expertise under one roof: from analysts & data scientists, chartered building services engineers, building controls and automation specialists, and chartered energy managers.

With this level of integrated expertise, we can help your organisation make the move from ‘dumb’ to ‘smart’ buildings, to save significant amounts of money, proactively manage and reduce carbon emissions, ensure compliance, and protect the value of your property assets.

Get in touch with the ETS team, to explore how we can help! Call 0117 379 0850 or email enquiries@energy-ts.com.